10/20/2014

Nitrocellulose is used in various industries as a fast-drying synthetic resin. Manufacturing nitrocellulose can be a dangerous process because it can easily explode if not properly handled. Our new supplier, Nitro Quimica has become the most technologically advanced nitrocellulose plant in the world. They are the only nitrocellulose producer that is certified by the National Association of Print Inks Manufacturers, and they offer the highest renewable raw material level in the industry.

Nitro Quimica has rigorous safety measures in place. All of their nitrocellulose is stored in fiber drums to reduce the risk of explosion associated with metal drums. Nitro Quimica has also developed a safer and easier method of releasing the product from the drum. Their drums have a rubber spout insert in the container that allows an air hose to be attached so users do not have to shake or hit the drum to remove the nitrocellulose.

Nitro Quimica is also concerned about the impact nitrocellulose and their company has on the environment. They offer wet blends of nitrocellulose with ethanol (Greencell) and IPA (Ecocell). Their Greencell line is made with 80% bio renewable content while their Ecocell line is made with 50% bio renewable content. Nitro Quimica is focused on the product’s beginning and end of life to help preserve environment.

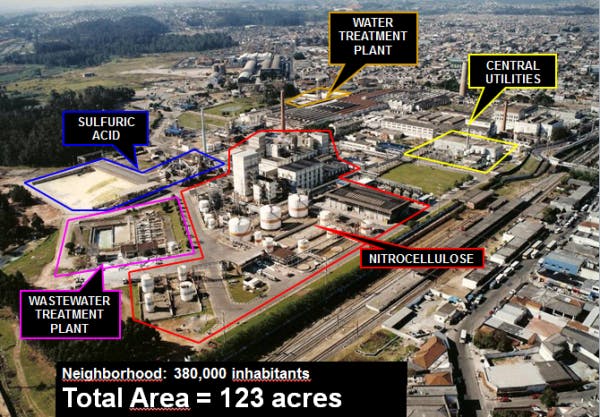

The focus for maintaining a healthy environment does not end with their products. Nitro Quimica’s plant strives to be self-sustaining. Currently, Nitro Quimica produces 50% of the energy they consume by transforming the steam created in the production process to generate electricity. They also have a water treatment plant and a wastewater treatment plant that takes the water from Rio Tieté and returns the water in cleaner condition.

Since 2004, Nitro Quimica has reduced their waste and effluents generation, their energy and water consumption have decreased, and their Sox and Cox Emission has gone down. At the same time, they have been able to increase their production volume, safety performance index, and all while improving their environmental performance.